STEP TWO – HOW TO INSTALL YOUR NEW INJECTION PUMP

As discussed in Step One, an important part of installing injection pumps correctly is getting the right shim for the new injection pump. If you have not reviewed this tech tip it is recommended that you start here. If you have gotten the correct pump, shim and have your rack locking pin and marking pin you are ready to replace your injection pump/pumps.

- Lock the rack with your rack locking pin. As you will recall from Step One, if not locked in the correct position your engine could be under fueling making it low on power, or worse over fueling which can lead to smoke, fuel dilution in the oil, excess fuel consumption, or possibly a melted piston if bad enough. Once the rack is locked in place you can ready your injection pump, but make sure to note which cylinder it came from.

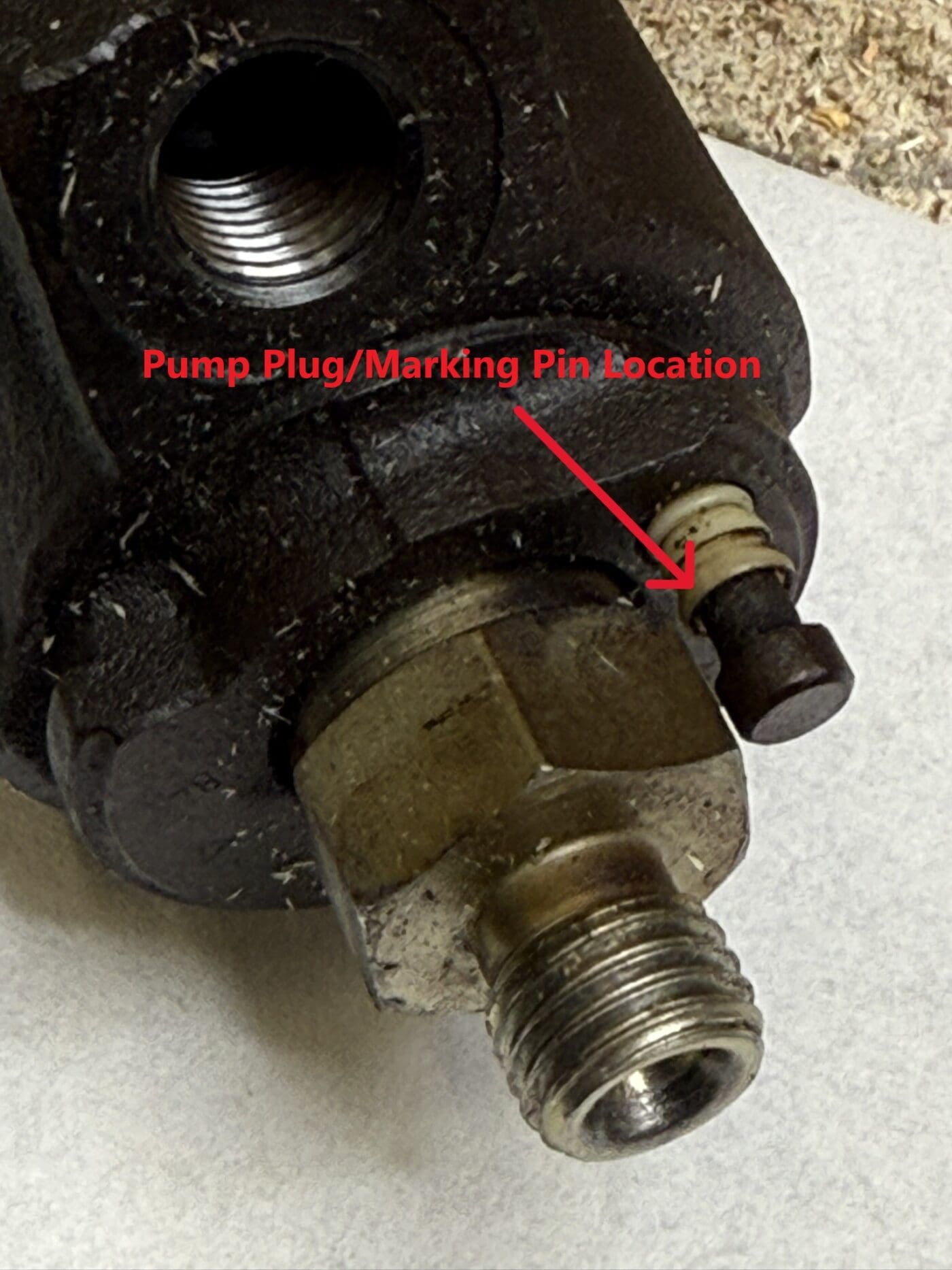

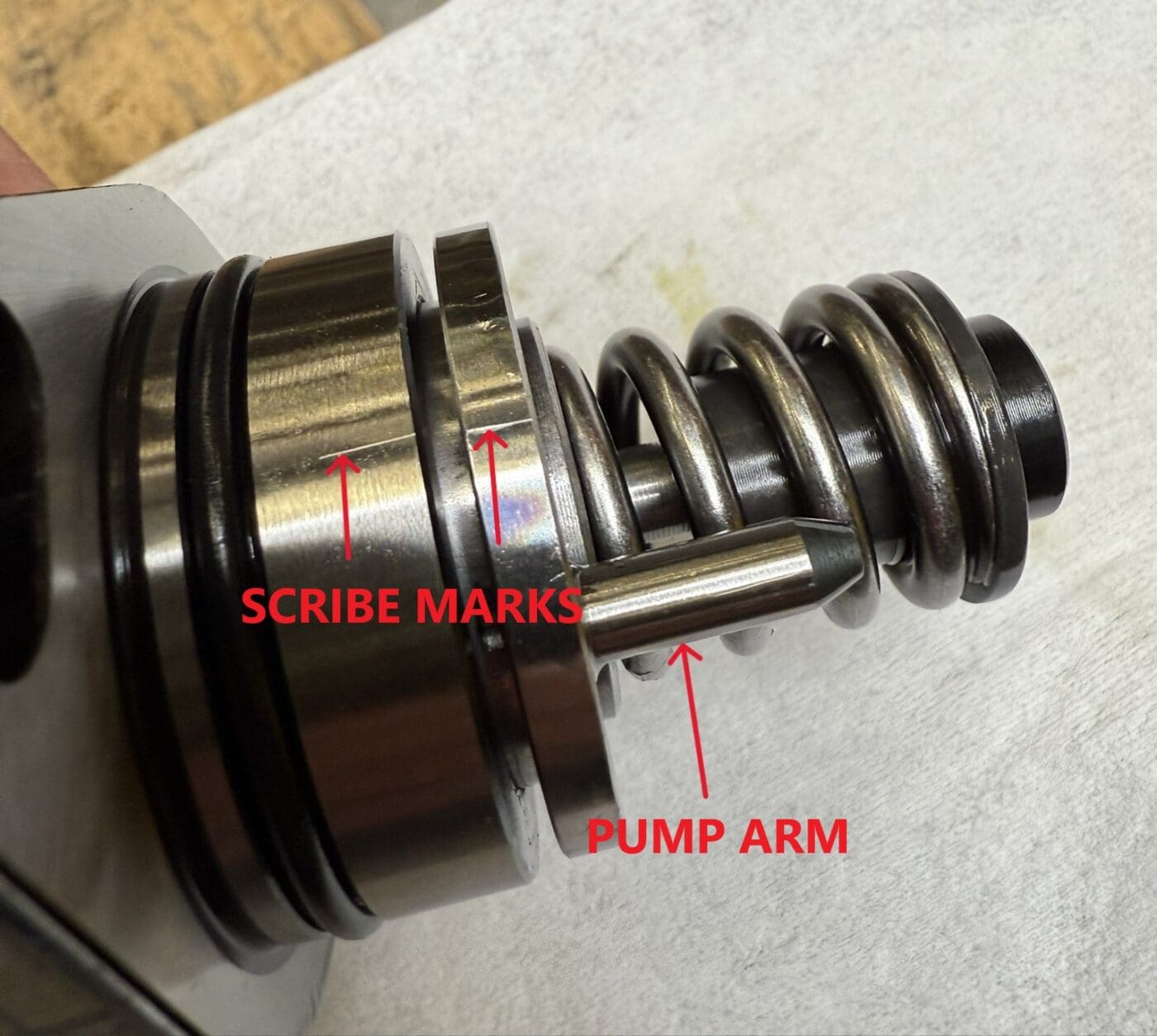

- Next, before replacing the injection pump, you will need to lock the injection pump actuating arm in place. If you have a new pump the hole for the pin should be open already. If you are reinstalling your old pump, you will need to remove the plug in the top of the injection pump next to the delivery valve. The plug is very small, only about 3/16th of an inch wide (see picture below). Remove this plug with a pair of pliers, it is not threaded but be sure to take care of the rubber insert on the plug as it can come off and get stuck in the bore of the pin hole. If it does get stuck, a pick and a little penetrating oil can help you get it out. Once removed you can partially insert the locking pin into the pump body. Looking at the injection pump from the side, on the lower half that sits below the mating surface of the block when installed, you will see a scribe mark on the injection pump body and another scribe mark on the rotating portion that seats in the rack (see picture below). Rotate the lower part until the two scribe marks are aligned and then insert the pin fully into the injection pump plug hole and rotate the pin to lock it in place around the groove on the pump delivery valve (the part of the injection pump the injection line from the injector attaches to). The injection pump should be locked in place now and you are ready to install it.

- For ease of installation and to make sure you don’t bend the fuel rack, be sure the tappet is at base circle (at the bottom) of the bore. Install the correct shim and make sure to face it correctly or it might interfere with the casting on the block (the “U” groove cutout on the shim should be facing outward/away from the block) (see picture below).

- Install the injection pump making sure to face it correctly, the fuel inlet port should be toward the outside of the engine. The fastening holes for the pump are slotted, as you are installing the pump it might not want to sit all the way in the bore. This can be caused by the rotating portion of the injection pump not aligning with the slot on the fuel rack. Rotate the injection pump until the pump falls into place. Once this happens, the fuel pump should be locked into position and should not rotate anymore. Go ahead and snug down the injection pump, remove the marking pin and replace the pump plug you removed earlier for the marking pin.

- Once you have completed replacing the fuel injection pump or pumps, remove the locking pin from the fuel rack. Verify the rack moves freely through the port the shutdown solenoid/actuator was removed from. If the rack moves freely, you have successfully installed the injection pump. If it does not, remove the installed pump/pumps and verify alignment again as well as that the rack has not been bent.

Once all the pumps have been installed, make sure to tighten everything down to the correct specifications and complete the assembly of everything else you were working on to finish your repairs. I hope this Tech Tip helps to shed some light on this process and saves you some time and headache.

Written by Dr. Diesel

Knowledge is power. To help our customers, we share tech tips summarizing some of our opinions, knowledge and information of interest that we have gathered since 1916 when Foley Engines opened for business. If you have any questions or comments, go to “Ask Dr. Diesel™” where you can pose questions about engines, clutches, exhaust scrubbers, etc.