Foley Industrial Engines

Industrial Engines and Parts

Specializing in industrial diesel engines for off-highway equipment and machines. Contact us today to keep your diesel engines running smoothly!

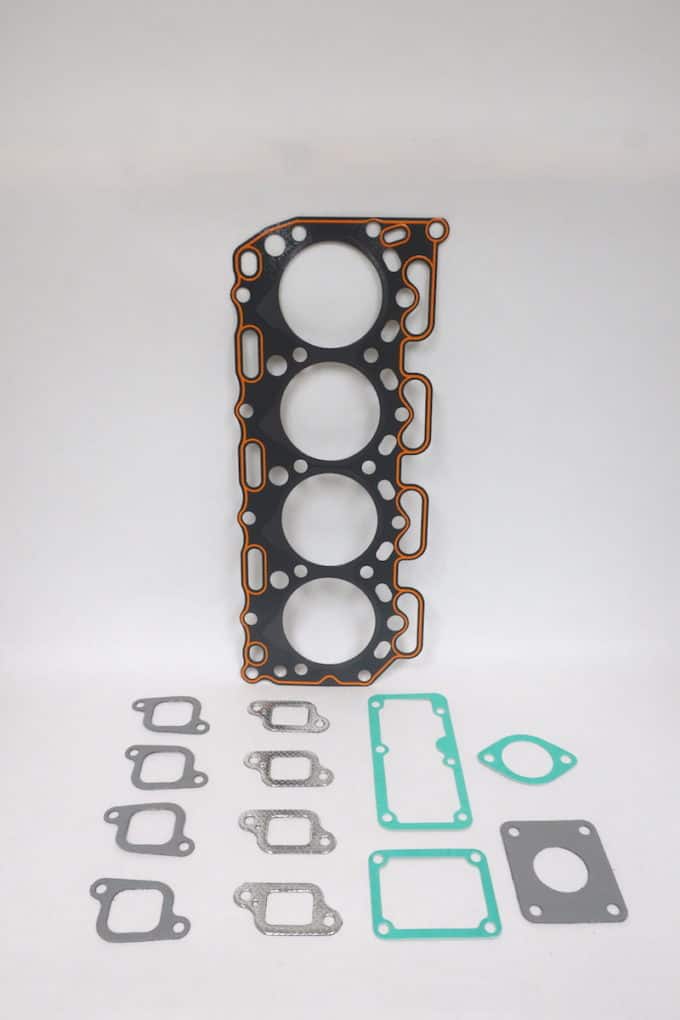

Popular Products

Previous

Next

New Products

Previous

Next

Recent Tech Tips

Previous

Next

Tech Tip #240: Twin Disc Shaft Lengths

- Posted In

-

- Categories

- Power Takeoffs

- Tech Tips

- Twin Disc

- Posted On

-

- Published

Tech Tip #239: Twin Disc / WPT IBF314 Pilot Bearing Installation Made Easy

- Posted In

-

- Categories

- Power Takeoffs

- Tech Tips

- Twin Disc

- WPT

- Posted On

-

- Published

Tech Tip #238: Ford Industrial Clutches Made Easy

- Posted In

-

- Categories

- Ford

- Power Takeoffs

- Rockford

- Tech Tips

- Twin Disc

- Posted On

-

- Published

Tech Tip #235: Cummins B Series Front Covers Made Easy

- Posted In

-

- Categories

- Cummins Tech Tips

- Tech Tips

- Posted On

-

- Published

Tech Tip #234: How to Change the Front Cover on a Cummins B Series Engine

- Posted In

-

- Categories

- Cummins Tech Tips

- Tech Tips

- Posted On

-

- Published

Tech Tip #233: Common Questions about Flywheels, Ring Gears, and Power Takeoffs

- Posted In

-

- Categories

- Power Takeoffs

- Rockford

- Tech Tips

- Twin Disc

- WPT

- Posted On

-

- Published

Tech Tip #232: Serial Numbers; Where and How to Find Them

- Posted In

- Posted On

-

- Published